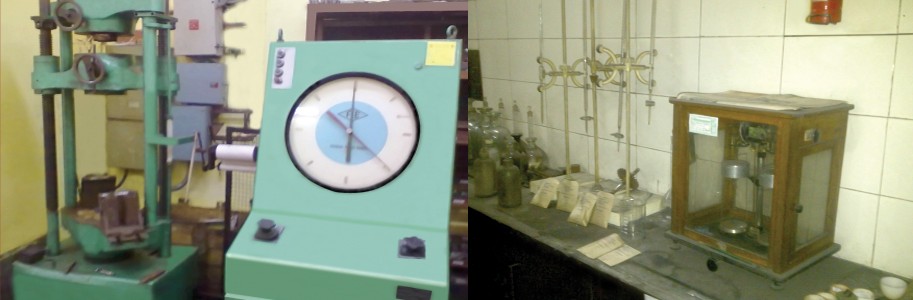

Quality is the key to the company’s growth. Right from Drawing to pattern, mould hardness to child test, casting (physical, Dimensional, Chemical) Painting & Packing, every step is carefully checked and monitored to ascertain the specified quality. Added to it all allied activities are subjected to stringent quality control. We have an In House laboratory for (Physical tests and chemical tests) and the most modern measuring instruments.

|

Sl.No

|

Nature of Test | Frequency of Test | Acceptability Norms | Reff.Doc. |

|

1

|

Compostion of Raw Materials

|

Every Lot

|

S-1.5 % (min.)

|

BooK

|

|

2

|

Pattern Dimensions

|

100% in every 3 months

|

Relevent Drg.

|

Book

|

|

3

|

Sand mix Characteristics

|

Every Heat

|

Mois. 5% & gcs -4 to 6%

|

Book

|

|

4

|

Mould Hardness

|

100%

|

Min.-40

|

Book

|

|

5

|

Tapping and Pouring Temp.

|

Every Heat

|

1150-Min

|

Book

|

|

6

|

Chill Test

|

Every Heat

|

3mm to 5mm

|

Book

|

|

7

|

Carbon equivalent Test

|

Every Heat

|

3.5% min.

|

Lab. Report

|

|

8

|

Visual Examination of Casting

|

100%

|

Free from Foundry Defect

|

Book

|

|

9

|

Sectionizing Test

|

Every Heat

|

Dimension, as per Customer Drg.

|

Sample

|

|

10

|

Surface Defects Examination of Finished Castings

|

100%

|

Free from foundry Defects

|

Book

|

|

11

|

Dimensional Check

|

100%

|

Customer’s Drg.

|

Int.Ins. Report

|

|

12

|

Chemical Composition

|

Every Heat

|

Customer Requier

|

Lab Report

|

|

13

|

Tensile Test

|

Every Heat

|

Customer Speci.

|

Lab Report

|

|

14

|

Hardness Test

|

Every Heat

|

Customer Speci.

|

Lab Report

|

|

15

|

Diamensions

|

100%

|

Customer Speci.

|

Int.Ins. Report

|

|

16

|

Paint Thickness

|

Sample

|

Customer Speci.

|

Int.Ins. Report

|